ممكن است هواي فشرده توليد شده داراي ناخالصيهايي نظير روغن، گردوغبار و رطوبت باشد. محيط اطراف نيز ممكن است بر كيفيت هواي فشرده تأثيرگذار باشد. به همين دليل هواي فشرده قبل از رسيدن به آخرين مرحله توليد بايد از فيلتر عبور كند.

Compressed Air Filters

The compressed air coming from the production line compressor may contain unwanted elements such as oil , dust and humidity The air in the external environment will also affect the quality of the final product, this air must be filtered prior to the final stage of production.

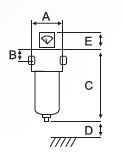

| Dimensions(mm) | Element type |

Flow rate m³ / h / scfm |

Air Connection |

MODEL | ||||

| E | D | C | B | A | ||||

| 22 | 100 | 193 | 19 | 72 | M24 | 24/14 | 1/4″ | HG 24 |

| 22 | 100 | 193 | 19 | 72 | M48 | 48/29 | 3/8“ | HG 48 |

| 22 | 110 | 237 | 20 | 96 | M25 | 25/15 | 1/4″ | HG 25 |

| 22 | 110 | 237 | 20 | 96 | M50 | 50/30 | 3/8“ | HG 50 |

| 22 | 150 | 237 | 20 | 96 | M100 | 100/58 | 1/2“ | HG 100 |

| 56 | 190 | 375 | 34 | 117 | M150 | 150/88 | 3/4“ | HG 150 |

| 56 | 250 | 375 | 34 | 117 | M200 | 200/117 | 3/4“ | HG 200 |

| 56 | 300 | 465 | 34 | 117 | M250 | 250/147 | 1“ | HG 250 |

| 56 | 350 | 465 | 34 | 117 | M300 | 300/176 | 1 ¼” | HG 300 |

| 56 | 380 | 530 | 34 | 117 | M500 | 500/294 | 1 ¼” | HG 500 |

| 56 | 425 | 530 | 34 | 117 | M600 | 600/353 | 1 ½” | HG 600 |

| 56 | 480 | 722 | 64 | 170 | M851 | 851/800 | 2“ | HG 851 |

| 56 | 550 | 722 | 64 | 170 | M1210 | 1210/712 | 2“ | HG 1210 |

| 56 | 430 | 760 | 72 | 235 | M1510 | 1510/888 | 2 ½” | HG 1510 |

| 56 | 550 | 760 | 72 | 235 | M1810 | 1810/1065 | 3“ | HG 1810 |

| 56 | 600 | 760 | 72 | 235 | M2210 | 2210/1300 | 3“ | HG 2210 |

| Activated Carbon | Oil removal | General purpose | Pre filtering | Specifications |

| A | Y | X | P | Grade |

| 0.01 | 0.01 | 1 | 5 | Particle removal(micron) |

| 0.003 | 0.01 | 0.5 | 5 | Max.oil carryover 21° C (mg/m³) |

| 25 | 80 | 80 | 80 | Max.working temperature |

| 80 | 100 | 80 | 40 | Initial pressure loss |

| 700 | 700 | 700 | 700 | Pressure loss for element change |

| 16 | 16 | 16 | 16 | Max.working pressure |

| Metal | Red | Blue | Green | Element color code |